How to maintain the common components of vertical machining center?

Time of issue:

2021-09-15

Servo motor and control system are the key parts of the power source and precision control of the machine tool, focusing on checking noise and temperature rise. If the noise or temperature rise is too large, it should be found out whether it is a mechanical problem such as a bearing or the parameter setting of the amplifier that matches it, and take corresponding measures to solve it.

1. Servo motor and spindle motor part of vertical machining center

Servo motor and control system are the key parts of the power source and precision control of the machine tool, focusing on checking noise and temperature rise. If the noise or temperature rise is too large, it should be found out whether it is a mechanical problem such as a bearing or the parameter setting of the amplifier that matches it, and take corresponding measures to solve it. If there is an abnormal sound during the movement of the servo shaft, it may be due to the mechanical noise caused by the screw, the coupling, and the non-concentricity with the servo motor. If there is still noise in the motor, adjust the gain of the speed loop and the gain of the position loop appropriately to make the motor silent. If there is no noise, it is judged that the concentricity of the screw and the coupling is the problem, re-correct the concentricity, and then connect to the motor, the problem can generally be eliminated .

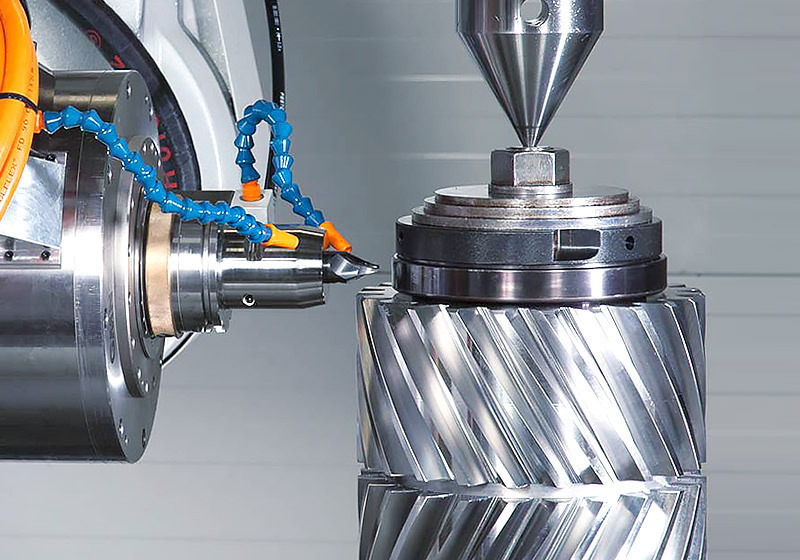

2. Vertical machining center measurement feedback element

The measurement feedback components include encoders, grating rulers, etc. It is necessary to frequently check to detect whether the connection of each component is loose, and whether it is contaminated by oil or dust. Dust and fine iron scraps may damage such components.

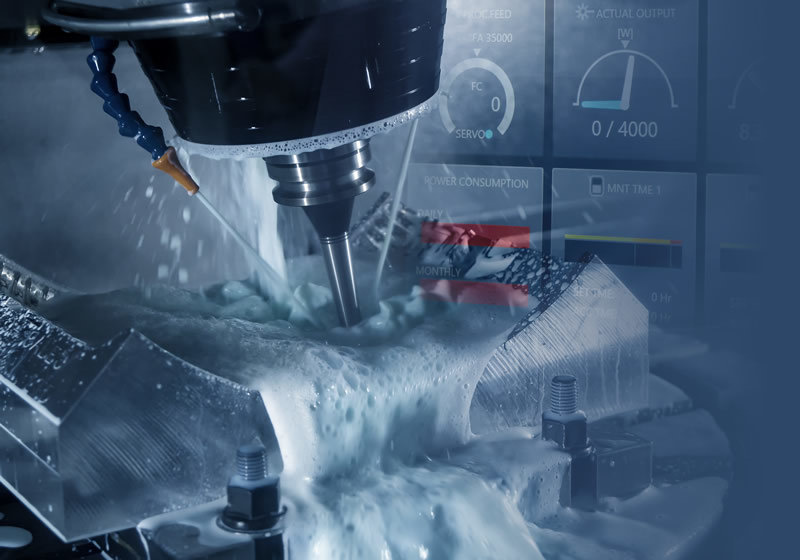

3. Electrical control part of vertical machining center

Always check whether the voltage of the external three-phase power supply connected to the machine tool is normal; check whether the electrical components are connected well; use the CRT to display the diagnostic screen to check whether various switches are effective; check whether the relays and contactors work normally and whether the contacts are good; thermal relays, Whether the protection components such as arc suppressor are effective; check whether the temperature of the components inside the electrical cabinet of the vertical machining center is too high. For the poor contact of the contactor, the contactor can be disassembled, the high-temperature oxide on the surface of the contact can be removed with a small file, and then the sundries can be wiped out with absorbent cotton and alcohol, reassembled, and then the contact is checked with a multimeter. Continuity test.

4. CNC system control part of vertical machining center

The control system includes numerical control unit, power module, I/O interface, servo amplifier, spindle amplifier, operation panel, display, etc. Maintenance is mainly to check whether the relevant voltage values are within the specified range; whether the connection of electrical components is loose; whether the fans of each functional module are running normally, and remove the dust on the fans and dust filters.

Mobile

Longboddy Precision Machinery Nantong Co, Ltd

Tel:86-13485119812 Mr Yang

86-13906296076 Mr Gu

E-mail:13485119812@126.com

PC:226300

Add:Group 18, Liuqiao Community, Industrial Concentration Zone, Liuqiao Town, Tongzhou District, Nantong City, Jiangsu Province

copyright © 2022 Longboddy Precision Machinery Nantong Co, Ltd