The research and development direction of CNC lathes in the future

Time of issue:

2021-09-15

With the promotion of Industry 4.0 and Made in China 2025 nationwide, China's manufacturing industry is brewing and undergoing earth-shaking changes. The development of robots and 3D printing has a profound impact on the CNC machine tool industry. Under this wave, How will the future development and production direction of the CNC machine tool industry change? Some predictions will be made below.

With the promotion of Industry 4.0 and Made in China 2025 nationwide, China's manufacturing industry is brewing and undergoing earth-shaking changes. The development of robots and 3D printing has a profound impact on the CNC machine tool industry. Under this wave, How will the future development and production direction of the CNC machine tool industry change? Some predictions will be made below.

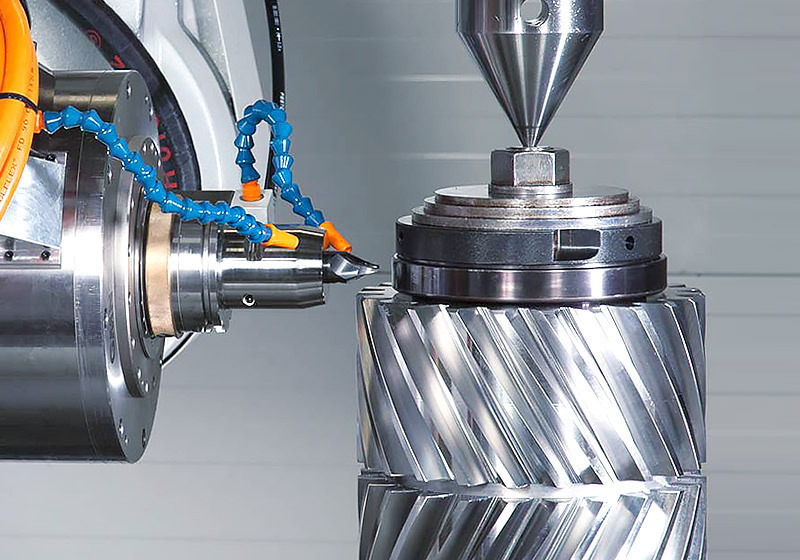

1. Compound machining technology is more widely used. New compound machining machine tools such as turning-milling and milling-turning compound machine tools, turning-grinding compound machine tools, gear-plus compound machine tools, turning-milling compound and 5-axis linkage machine tools and other products continue to emerge; heavy-duty machine tools increase multi-function For accessories and turntables, the trend of composite processing is obvious; new progress has been made in the composite of metal cutting and special processing, and the composite technology of laser, electrical machining and cutting processing has been matured for product promotion and application. The promotion and application of composite processing technology will have an important impact on the production process of multi-variety and small batches.

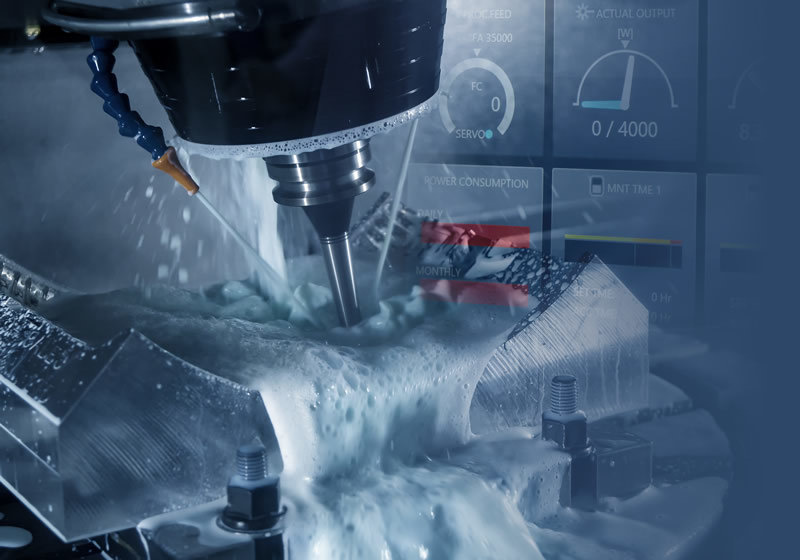

2. The application speed of direct drive technology is accelerated. Due to the advancement of power electronics and numerical control technology, as well as the maturity of linear motors, torque motors, electric spindles, grating detection and other components, the application speed of direct drive technology in CNC machine tools is accelerated, and many foreign machine tool companies The new products have been driven by linear motors. The application of direct drive technology will greatly promote the structural change and performance improvement of CNC machine tools.

3. Micro-manufacturing technology is emerging Micro-manufacturing (Inter-Micro) refers to a new efficient, green and high-precision micro-manufacturing technology for processing various micro parts in 3D shapes. At present, under the funding of the European Union, research groups composed of universities, research institutes and enterprises in Germany, Italy and other relevant countries have achieved relevant results, such as: ultra-precision 5-axis linkage micro-diamond and cubic boron nitride tool processing technology and equipment, etc. . Micro-fabrication technology has great application potential and should attract the attention of the industry.

Mobile

Longboddy Precision Machinery Nantong Co, Ltd

Tel:86-13485119812 Mr Yang

86-13906296076 Mr Gu

E-mail:13485119812@126.com

PC:226300

Add:Group 18, Liuqiao Community, Industrial Concentration Zone, Liuqiao Town, Tongzhou District, Nantong City, Jiangsu Province

copyright © 2022 Longboddy Precision Machinery Nantong Co, Ltd