Reasons for the vibration of the screw of the gantry machining center

Time of issue:

2021-09-15

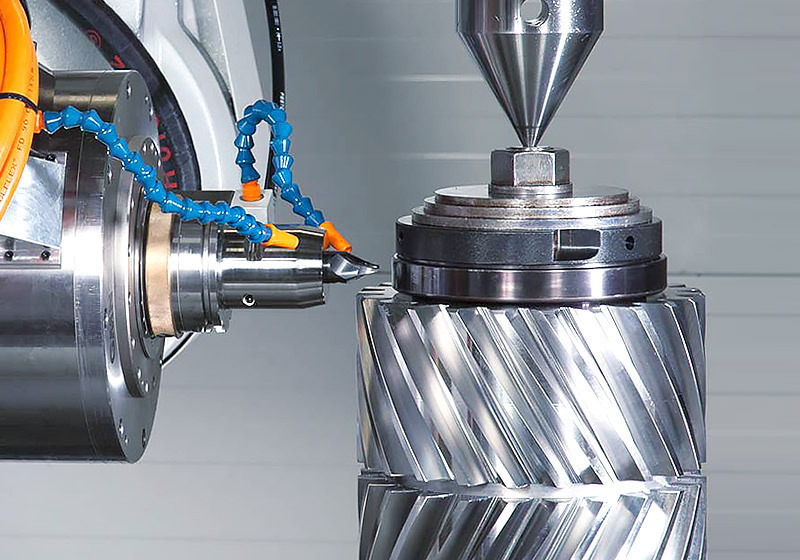

The reason for the vibration of the lead screw of the gantry machining center may be the electrical parameter error of the system or the reason of the lead screw itself. When the lead screw vibrates, it should be dealt with in time to avoid damage to the parts and ensure the processing of the machine tool. The following will explain the reasons for the vibration of the lead screw.

The reason for the vibration of the lead screw of the gantry machining center may be the electrical parameter error of the system or the reason of the lead screw itself. When the lead screw vibrates, it should be dealt with in time to avoid damage to the parts and ensure the processing of the machine tool. The following will explain the reasons for the vibration of the lead screw.

1. Improper installation of the screw

The screw of the gantry machining center is generally a ball screw with high transmission accuracy, and it also has high requirements for the accuracy of installation. If the error is large during the installation process, the lead screw will be bent and deformed during the movement of the carriage, and then the lead screw will vibrate due to uneven force.

2. Improper installation and connection of screw nuts or pallets

The installation surface is not perpendicular to the reference (rail) surface, that is, the installation surface is not parallel to the joint surface of the lead screw nut, which causes the lead screw to deform and vibrate after the tightening screw of the lead screw nut.

Third, the reason of the coupling

The motor and the lead screw are connected and rotated through the coupling. If the following conditions are not met, vibration will occur: 1. The radial runout error at the end of the lead screw must meet the design requirements; 2. The motor The installation surface is perpendicular to the axis of the lead screw, and the axis of rotation of the motor coincides with the axis of the lead screw, which is generally guaranteed by the design requirements of the positioning holes; 3. Evenly tighten the expansion sleeve gland on the coupling with a torque wrench. screw.

4. Reasons for the axial clearance of the screw

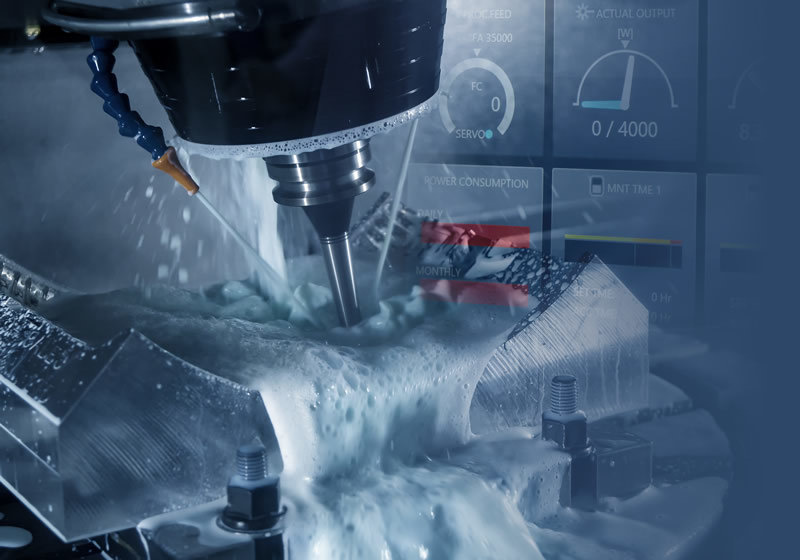

During the movement of the carriage, if the axial clearance of the lead screw is too large, vibration will also occur, including the creeping phenomenon of the carriage. This is because the CNC axis itself has a grating ruler. When the grating ruler is in effect, according to the feedback of the grating signal, the servo motor will continuously rotate forward and reverse to correct the position of the carriage. The speed is uneven and vibration is generated.

Five, bearing quality problems

Judging from the sound, during the movement of the carriage, if the carriage is closer to the support seat at one end of the lead screw, the higher the vibration frequency of the lead screw, the bearing at this end may have a problem.

In addition, the lubrication of the machine tool is not enough, the guide rail is worn, or the motor encoder failure may cause the lead screw to vibrate. In this case, it should be checked step by step. The above is the analysis of the reasons for the vibration of the screw of the gantry machining center, and find the appropriate solution according to the reasons to ensure the service life

Mobile

Longboddy Precision Machinery Nantong Co, Ltd

Tel:86-13485119812 Mr Yang

86-13906296076 Mr Gu

E-mail:13485119812@126.com

PC:226300

Add:Group 18, Liuqiao Community, Industrial Concentration Zone, Liuqiao Town, Tongzhou District, Nantong City, Jiangsu Province

copyright © 2022 Longboddy Precision Machinery Nantong Co, Ltd