How to shorten the processing time of machining center

Time of issue:

2021-09-15

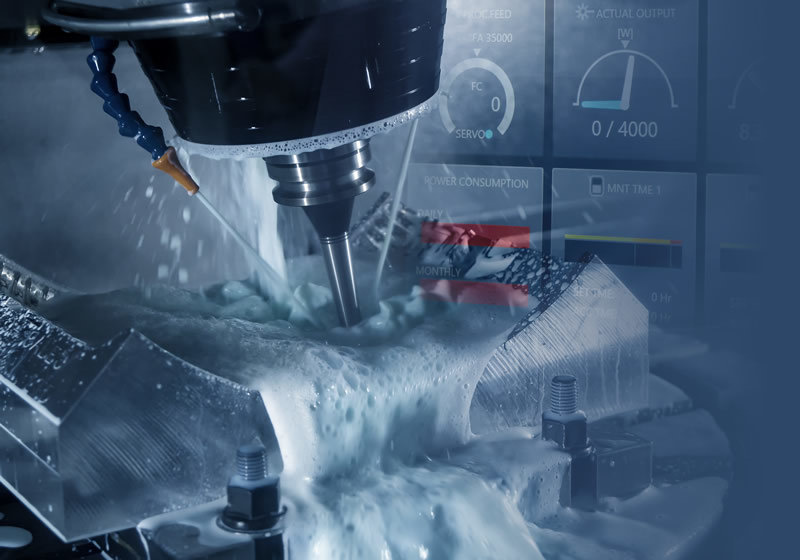

Before answering the question of "how to shorten the processing auxiliary time of the machining center", let's first understand what is the auxiliary processing time of the machining center.

1. How to shorten the auxiliary processing time of the machining center

Before answering the question of "how to shorten the processing auxiliary time of the machining center", let's first understand what is the auxiliary processing time of the machining center. The processing auxiliary time of the machining center is the mechanical movement time of some non-direct machining workpieces, such as aligning the workpiece, tool setting time, tool changing time, etc. The time occupied by these mechanical movements is called the processing center processing auxiliary time.

So how can we shorten the auxiliary time of the machining center? For the alignment and tool setting of the workpiece, we can use the process positioning platform on the machining center. For tool change, you can choose some tool magazines with fast tool changing speed, such as the bucket hat type tool magazine and the tool arm type tool magazine used in the machining center. Choosing the tool arm type tool magazine can save the tool change time.

2. What are the advantages of using the process positioning platform for the machining center?

The process positioning platform eliminates the need for table alignment and tool setting in the x and y directions when installing the workpiece. Compared with traditional auxiliary operations, it can save about 90% to 95% of auxiliary time, and the utilization rate of machine tools is increased from 57% to 68% of traditional auxiliary operations to 92% to 96%. The depreciation cost of the machining center can also be greatly reduced, and the economic benefits are very obvious. And it can clamp multiple workpieces, especially the processing of small parts, the benefits are more obvious. The traditional workpiece clamping method completes all the processing work required by the processing procedure after the workpiece is installed once, and cannot be replaced with other workpieces for expedited processing in the middle. After using the general process positioning platform, as long as the workpiece or fixture positioning datum meets the requirements of the positioning platform, other workpieces that need to be processed can be replaced at any time for processing. After completion, the workpieces removed in the middle can be quickly positioned and clamped to continue processing. . This gives CNC milling machines and machining centers a great deal of flexibility.

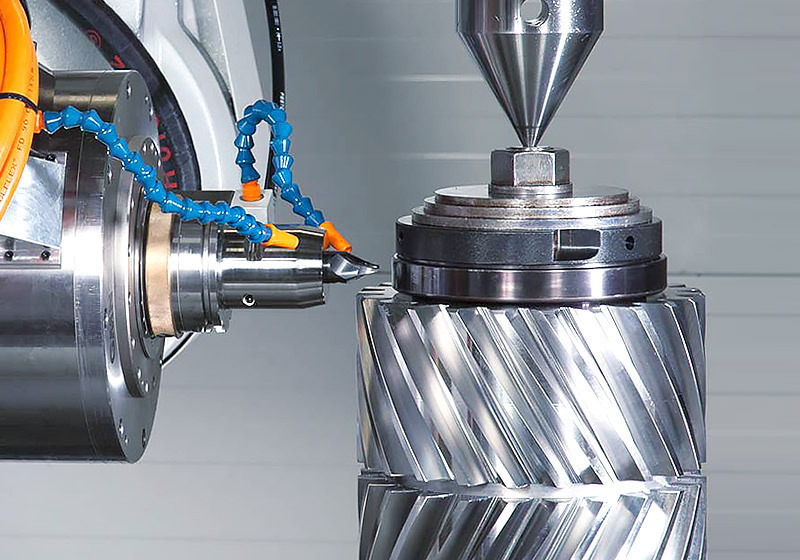

Machining center processing

3. The selected tool magazine of the machining center can improve the tool changing speed

There are many different types of tool magazines in machining centers, such as bucket hat type, knife arm type, synchronous type, flying saucer type and many other types of tool magazines. The tool magazines used in ordinary vertical machining centers are only bucket hat type and tool arm type. The tool change speed of the tool arm type tool magazine can save 50% of the time than the bucket hat type tool magazine. If it is used in batch processing, it is more suitable to use the tool arm type tool magazine. The synchronous tool magazine and the flying saucer-type tool magazine are unique tool magazines for high-speed machining centers and drilling and tapping centers. The tool magazine for high-speed machine tools also has a tool-arm tool magazine, and the tool changing speed of these two tool magazines Both are much faster than the tool arm type tool magazine, and the tool change can be completed within seconds, which can save processing auxiliary time, but the effect is not as obvious as the comparison between the bucket hat type tool magazine and the tool arm type tool magazine.

Mobile

Longboddy Precision Machinery Nantong Co, Ltd

Tel:86-13485119812 Mr Yang

86-13906296076 Mr Gu

E-mail:13485119812@126.com

PC:226300

Add:Group 18, Liuqiao Community, Industrial Concentration Zone, Liuqiao Town, Tongzhou District, Nantong City, Jiangsu Province

copyright © 2022 Longboddy Precision Machinery Nantong Co, Ltd