What are the basic precautions for turning centers?

Time of issue:

2021-09-15

Provide safety training to relevant personnel. Safety training should be carried out for the relevant staff of the turning center, so that they can master the use of the equipment, and understand the use technology and safety regulations. Only in this way, they can ensure personal safety when operating the machine tool, and at the same time play a role in safety protection of the machine tool. Of course, for different products and components, efficient production must be carried out.

1. Provide safety training to relevant personnel. Safety training should be carried out for the relevant staff of the turning center, so that they can master the use of the equipment, and understand the use technology and safety regulations. Only in this way, they can ensure personal safety when operating the machine tool, and at the same time play a role in safety protection of the machine tool. Of course, for different products and components, efficient production must be carried out.

2. Do not operate illegally. In the process of machining parts with a turning center, due to the different production technicians in each post, some basic matters that should be paid attention to are also different. Therefore, operators who operate machine tools must meet the requirements when they take up their jobs, especially those who cannot take jobs after drinking or other illegal operations.

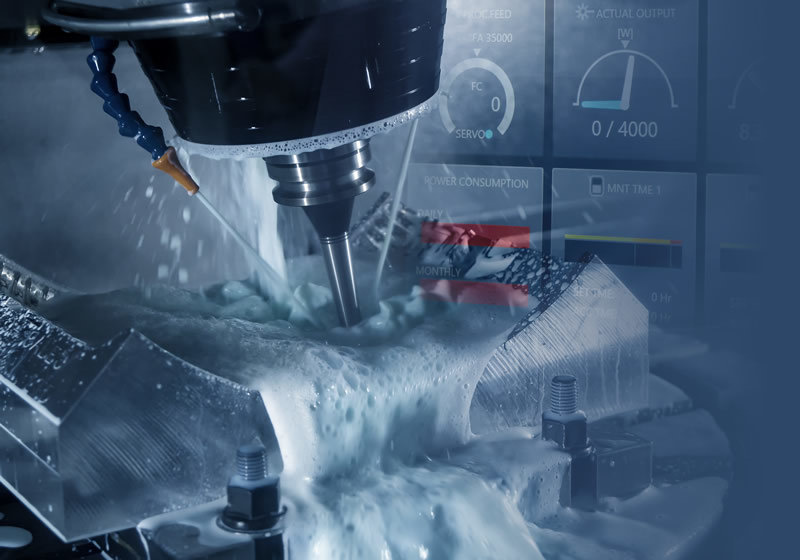

Third, it is necessary to pay attention to safety production. Before the daily operation of the turning center, it is necessary to obtain the safety technical disclosure of the team leader or other relevant leaders, so that each operator can pay more attention to the production and processing of the machine tool and the safe and convenient post office. Fourth, pay attention to environmental factors. Turning centers need to pay attention to environmental factors during operation, especially the current and voltage requirements for the environment are quite high. If the ambient temperature or humidity is too high, it is likely to have some impact on the product quality.

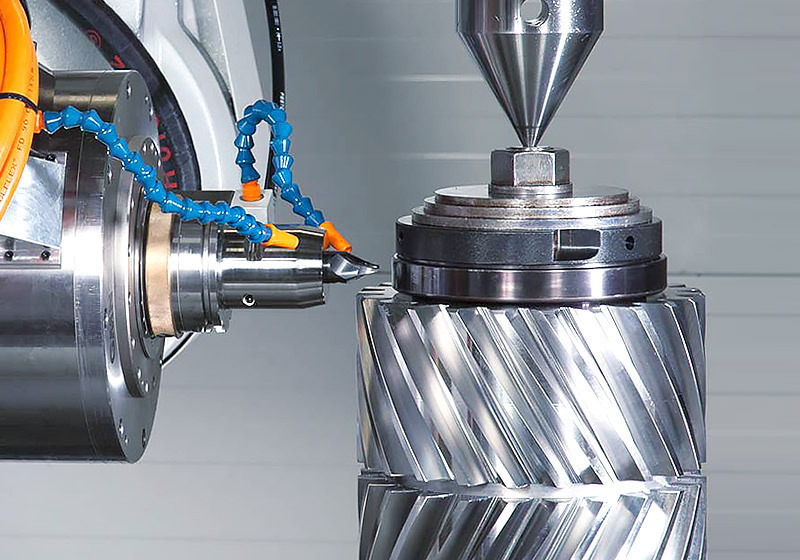

On the basis of ordinary CNC lathes, the turning center adds a C-axis and a power head. The more advanced CNC lathes have tool magazines, which can control the three coordinate axes of X, Z, and C. The linkage control axis can be (X, Z), (X, C) or (Z, C). The machining capabilities of this CNC lathe are greatly enhanced thanks to the addition of a C-axis and a milling power head. In addition to ordinary turning, it can also be used for radial and axial milling, surface milling, drilling holes and radial holes whose centerline is not in the center of the part turning, etc.

Because each business or enterprise has different requirements for products and parts, especially the specifications and quantities of products. Therefore, before using a lathe turning center to process parts, the operator should understand the purpose of this operation and what the operating standards are, so as to ensure that each operator can understand his job responsibilities and have a deep understanding of his own work content. and master.

It should also be noted that every time the parts are processed in the turning center, the environment of the machine tool needs to be cleaned to ensure a pollution-free environment, which will have a certain impact on the product quality and prolong the service life of the lathe.

Mobile

Longboddy Precision Machinery Nantong Co, Ltd

Tel:86-13485119812 Mr Yang

86-13906296076 Mr Gu

E-mail:13485119812@126.com

PC:226300

Add:Group 18, Liuqiao Community, Industrial Concentration Zone, Liuqiao Town, Tongzhou District, Nantong City, Jiangsu Province

copyright © 2022 Longboddy Precision Machinery Nantong Co, Ltd