Operation precautions of horizontal machining center

Time of issue:

2021-09-15

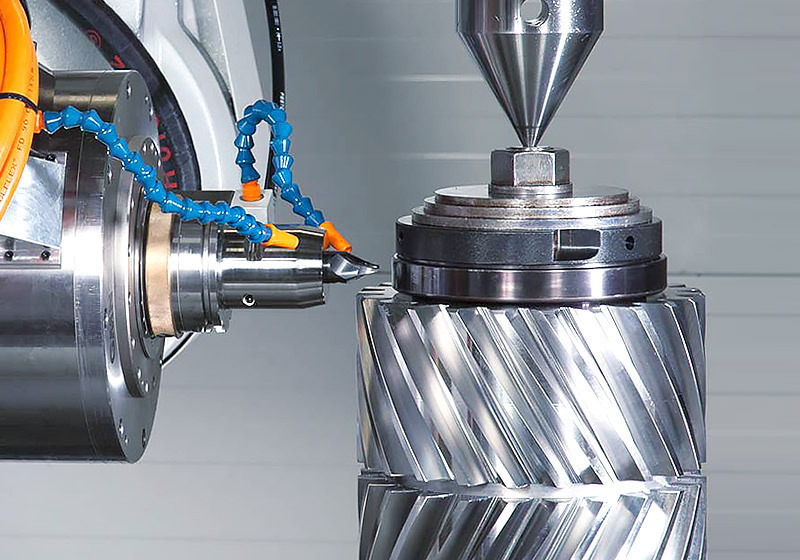

The horizontal machining center refers to the machining center with the spindle axis parallel to the worktable. It is mainly suitable for machining box parts. Its working principle is that after the workpiece is clamped once in the machining center, the computer can automatically select different tools and automatically change the machine tool.

Operation precautions of horizontal machining center

Precautions for Horizontal Machining Centers

The horizontal machining center refers to the machining center with the spindle axis parallel to the worktable. It is mainly suitable for machining box parts. Its working principle is that after the workpiece is clamped once in the machining center, the computer can automatically select different tools and automatically change the machine tool. The spindle speed of the CNC horizontal machining center should be paid attention to in order to complete the multi-process processing of multiple surfaces of the workpiece in turn:

1. The CNC horizontal machining center should be kept away from the vibration source, and the influence of direct sunlight and heat radiation should be avoided, and the influence of humidity and airflow should be avoided. If there is a vibration source near the CNC machine tool, an anti-vibration groove should be set around the machining center, otherwise it will directly Affect the machining accuracy and stability of CNC machine tools, poor contact of electronic components, failures, and affect the reliability of the machining center.

2. The CNC horizontal machining center is generally installed in the machining workshop. Not only does the ambient temperature change greatly and the operating conditions are poor, but also there are many types of mechanical and electrical equipment, resulting in large fluctuations in the power grid. Therefore, the location of the installation machining center needs to strictly control the power supply voltage. The fluctuation must be within the allowable range and remain relatively stable, otherwise it will affect the normal operation of the CNC system of the machining center.

3. The ambient temperature of the CNC horizontal machining center is lower than 30 degrees Celsius, and the relative temperature is less than 80%. Generally speaking, an exhaust fan or a cooling fan is installed inside the CNC cabinet to keep the working temperature of electronic components, especially the central processing unit constant. Or the temperature difference does not change much, too high temperature and humidity will reduce the service life of the control system components, leading to more failures, with the increase of temperature and humidity, the increase of dust will cause bonding on the integrated circuit board, resulting in short circuit .

4. When the user uses the CNC horizontal machining center, it is not allowed to change the parameters set by the manufacturer in the control system at will. The setting of these machining center parameters is directly related to the dynamic characteristics of each part of the machining center. Only the gap compensation parameter value can be used. Adjust according to the actual situation.

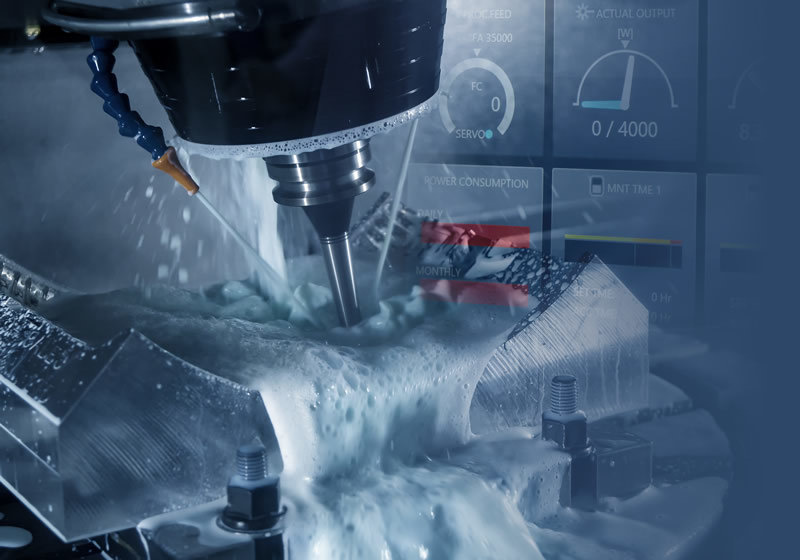

Preparation of products processed by horizontal machining center

Before operating the machining center, you must understand the general characteristics, structure, transmission system principle and management procedures of the CNC machine tool, master the functions of all operation keys and display lights, and the operation procedure flow. Before understanding the entire operation process, it is not necessary to carry out the operation of the machine tool Operation and adjustment, before starting the machining center, check whether the automatic control system of the electrical equipment of the machine tool is normal, whether the air intake system is smooth, whether the oil is good, whether each operating rocker is filled with appropriate grease according to regulations, and whether the product workpiece, fixture, Check whether the CNC blade is firmly clamped, check whether there is enough refrigerant, and then drive slowly for 3 to 5 minutes at high speed to check whether the components of the transmission system are normal, and it can be used normally if there is no problem.

After the debugging process is over, you must obtain the consent of the instructor, operate according to the process, and are not allowed to skip the process. Without the approval of the instructor, if you operate privately or violate traffic laws, the test score will be zero, and those who cause a safety accident will be subject to relevant requirements. Punishment and pay the corresponding compensation. Before the machining center produces and machined parts, it is necessary to strictly check whether the starting point of the machine tool and the data information of the CNC blade are all normal, and carry out the simulation operation of the movement trajectory without drilling.

Mobile

Longboddy Precision Machinery Nantong Co, Ltd

Tel:86-13485119812 Mr Yang

86-13906296076 Mr Gu

E-mail:13485119812@126.com

PC:226300

Add:Group 18, Liuqiao Community, Industrial Concentration Zone, Liuqiao Town, Tongzhou District, Nantong City, Jiangsu Province

copyright © 2022 Longboddy Precision Machinery Nantong Co, Ltd