LHV vertical and horizontal composite machining center

Category:

Key words:

Tel:

Description

This model is specially developed for complex parts, suitable for non-five-axis linkage of complex parts, can realize a clip five-sided processing, so as to save customers labor, realize a clip multi-process processing, to provide customers with efficient and fine parts products.This machine can also be matched with five axis system to achieve five axis linkage, processing impeller and curved artifacts.

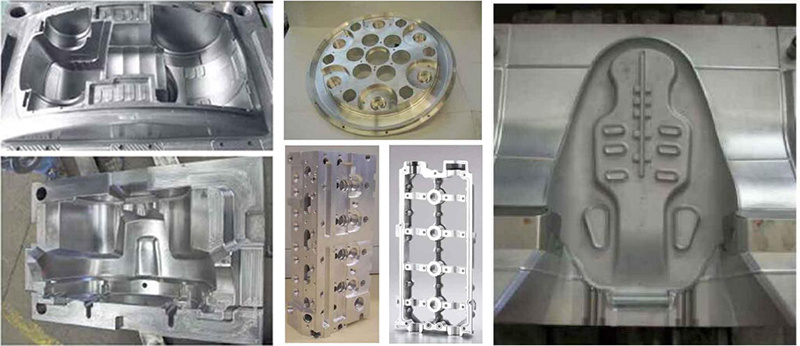

Machining workpiece

Main Specifications

| Project name | Unit | LHV630 Recumbent Processing Center | LHV500 Recumbent Processing Center | ||

| Workbench | Operating area(width*length) | mm | 630*630 | 500*500 | |

| Number of workbench | Only | 1 | 1 | ||

| Maximum load weight | kg | 800 | 600 | ||

| Workbench score | Degree | 1x360°/0.001° | 1x360°/0.001° | ||

| Workbench drive ratio | i | 90/120 | 90/120 | ||

| Travel | Workbench Left to Right Mobile (X) | mm | 1100 | 800 | |

| Spindle box to move up and down(Y) | mm | 800 | 650 | ||

| Column front and rear movement(Z) | mm | 800 | 650 | ||

| 主轴 Spindle | Spindle cone | BBT40/HSK63A | BBT40/HSK63A | ||

| Power of spindle motor | kW | 20/30 | 20/30 | ||

| Maximum speed of spindle | rpm | 16000-20000 | 16000-20000 | ||

| The spindle has a maximum output of torque | N.m | 70/150 | 70/150 | ||

| Main dle end to bench center (minimum/maximum) | mm | 200-1000 | 150-800 | ||

| Distance from the spindle centerline to the worktop | mm | 200-1000 | 150-800 | ||

| A axis swing trip | 。 | ±120 | ±120 | ||

| A axis fractions | 。 | 1/5/7.5 | 1/5/7.5 | ||

| A axs positioning mode | Comcomb disc/hydraulic lock | Comcomb disc/hydraulic lock | |||

| Into Give | Torque of servo motor | N.m | X:22 Y:30B Z:30 A:12 C:22 | X:22 Y:30B Z:30 A:12 C:22 | |

| X/Y/Z/W fast-moving speed | m/min | 24 | 24 | ||

| A axis | r/min | 12 | 12 | ||

| C axis | r/min | 4 | 4 | ||

| Fine Degree | The X/Y/Z/W-axis positioning accuracy | mm | 0.006/300 | 0.006/300 | |

| The A-axis positioning accuracy | " | ±10 | ±10 | ||

| The C-axis positioning accuracy | " | ±6 | ±6 | ||

| The X/Y/Z/W-axis repeated positioning accuracy | mm | 0.004/300 | 0.004/300 | ||

| The A-axis repeated positioning accuracy | ” | ±5 | ±5 | ||

| The C-axis repeated positioning accuracy | ” | ±4 | ±4 | ||

| The knife Library With Place | Number of knives | Put | BBT40/HSK63-24 | BBT40/HSK63-24 | |

| Maximum diameter of tool (adjacent blade holder) | mm | Φ78 | Φ78 | ||

| Maximum tool diameter (adjacent blade seat) | mm | Φ120 | Φ120 | ||

| Maximum length of tool | mm | 300 | 300 | ||

| Maximum allowable weight of the tool | kg | 8 | 8 | ||

| Its He | Outline size of machine tool (long*width*height) | mm | 4425*3200*3300 | 3825*3200*2900 | |

| Total weight of machine tool | kg | (About)9500 | (About)7500 | ||

Related Products

Messages

Mobile

Longboddy Precision Machinery Nantong Co, Ltd

Tel:86-13485119812 Mr Yang

86-13906296076 Mr Gu

E-mail:13485119812@126.com

PC:226300

Add:Group 18, Liuqiao Community, Industrial Concentration Zone, Liuqiao Town, Tongzhou District, Nantong City, Jiangsu Province

copyright © 2022 Longboddy Precision Machinery Nantong Co, Ltd