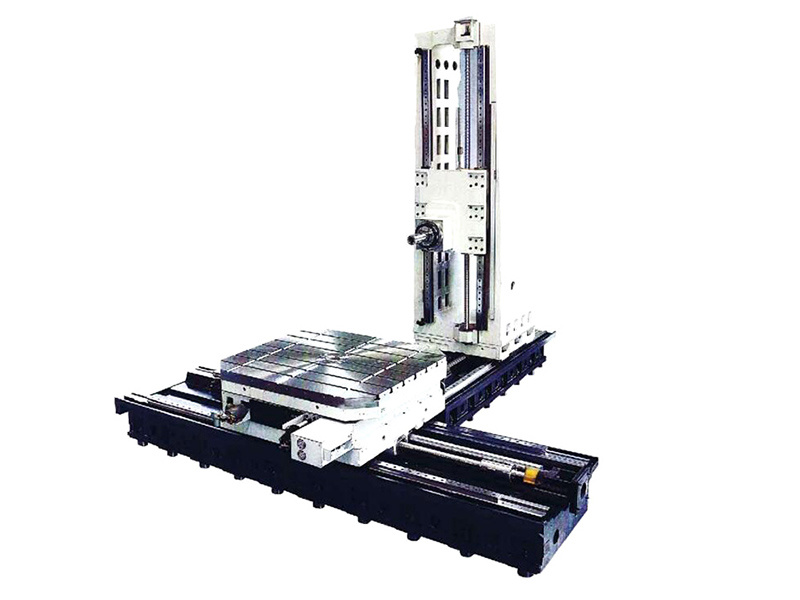

LHT spindle center type boring and milling machining center series

Category:

Key words:

Tel:

Description

This machine tool is suitable for the processing of small and medium-sized boxes. It is equipped with a mobile disc tool magazine, which effectively makes up for the disadvantages of high price and long tool change time of the side-mounted tool magazine, thereby saving costs and improving processing efficiency for users. The spindle center type boring and milling machining center is divided into two types: planer type and cross slide type. The planer type is suitable for larger turntables and the cross slide type is suitable for turntables below 1400.

Main Specifications

| Project name | Unit | LHT110A Boring and Milling Processing Center | LHT110B Boring and Milling Processing Center | LHT110 Boring and Milling Processing Center | ||

| Workbench | Operating area(width*length) | mm | 800*800 | 1000*1000 | 630*630 | |

| Number of workbench | Only | 1 | 1 | 1 | ||

| Maximum load weight | kg | 1500 | 2000 | 800 | ||

| Workbench score | Degree | 1x360/0.001° | 1x360/0.001° | 1x360/0.001° | ||

| Workbench drive ratio | i | 240 | 360 | 240 | ||

| Travel | Workbench Left to Right Mobile(X) | mm | 1300 | 1300 | 1100 | |

| Spindle box to move up and down(Y) | mm | 1000 | 1000 | 800 | ||

| Column front and rear movement(Z) | mm | 1000 | 1000 | 800 | ||

| Boring rod Expansion(W) | mm | 500 | 500 | 500 | ||

| Spindle | Spindle cone | BT50 | BT50 | BT50 | ||

| Boringrod diameter | mm | Φ110 | Φ110 | Φ110 | ||

| Power of spindle motor | kW | 15/18.5 | 15/18.5 | 15/18.5 | ||

| Maximum speed of spindle | rpm | 1500 | 1500 | 1500 | ||

| Main dle end to bench center (minimum/maximum) | mm | -250-1250 | -200-1300 | -300-1000 | ||

| Distance from the spindle centerline to the worktop | mm | 300-1300 | 300-1300 | 300-1100 | ||

| Into Give | Torque of servo motor | N.m | X30Y.45BZ:45C30W22 | X30Y:45BZ:45 C30W22 | X30Y:458Z45C30W22 | |

| X/Y/Z/W fast-moving speed | m/min | 12/12/10/8 | 10/10/10/8 | 12/12/10/8 | ||

| C axis | r/min | 1.5 | 1 | 1.5 | ||

| Fine Degree | The X/Y/Z/W-axis positioning accuracy | mm | 0.006/300 | 0.006/300 | 0.006/300 | |

| The C-axis positioning accuracy | ” | ±10 | ±10 | ±10 | ||

| The X/Y/Z/W-axis repeated positioning accuracy | mm | 0.004/300 | 0.004/300 | 0.004/300 | ||

| The C-axis repeated positioning accuracy | ” | ±5 | ±5 | ±5 | ||

| The knife Library With Place | Number of knives | Put | BT50-24 | BT50-24 | BT50-24 | |

| Maximum dameter of tool taciacent blade hoider | mm | Φ112 | Φ112 | Φ112 | ||

| Maximum tool dameter (adjacent blade seat) | mm | Φ200 | Φ200 | Φ200 | ||

| Maximum length of tool | mm | 300 | 300 | 300 | ||

| Maximum allowable weight of the tool | kg | 18 | 18 | 18 | ||

| Its He | outtine size of machine tool (long"widh"height) | mm | 5425*4200*3300 | 5425*4200*3300 | 4425*3200*3300 | |

| Total weight of machine tool | kg | (About)12000 | (About)13000 | (About)10000 | ||

Related Products

Messages

Mobile

Longboddy Precision Machinery Nantong Co, Ltd

Tel:86-13485119812 Mr Yang

86-13906296076 Mr Gu

E-mail:13485119812@126.com

PC:226300

Add:Group 18, Liuqiao Community, Industrial Concentration Zone, Liuqiao Town, Tongzhou District, Nantong City, Jiangsu Province

copyright © 2022 Longboddy Precision Machinery Nantong Co, Ltd